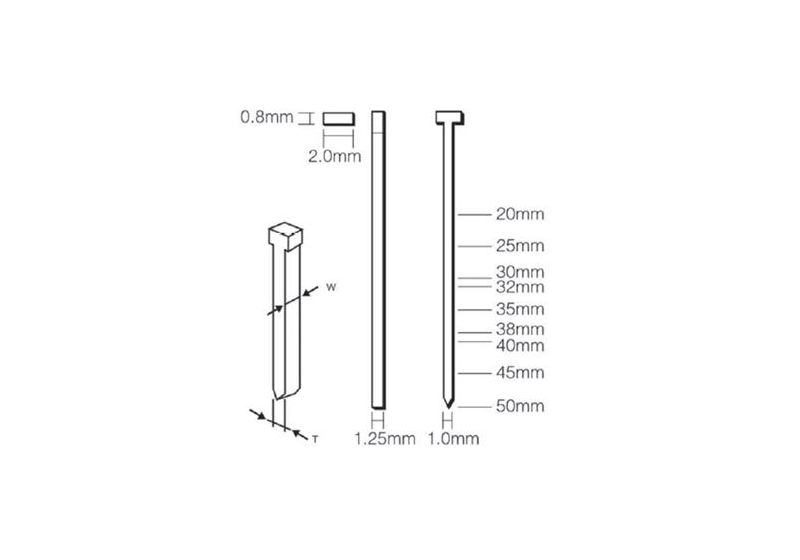

RSCO F type Nail for Air tool model F1

The Versatility and Efficiency of Air Tools and Equipment

Air tools, also known as pneumatic tools, are powered by compressed air supplied by an air compressor. These tools are widely used in various industries, including automotive, construction, and manufacturing, due to their efficiency, durability, and versatility. This essay explores the different types of air tools, their applications, and the benefits they offer.

Types of Air Tools

1 Air Impact Wrenches: These tools are essential in automotive repair and assembly lines. They deliver high torque output, making it easy to loosen or tighten bolts and nuts quickly and efficiently.

2 Air Hammers: Used in construction and metalworking, air hammers are ideal for cutting, chipping, and shaping metal. They are also used for removing rust or old paint from surfaces.

3 Air Grinders: These are used for grinding, polishing, and cutting materials. They are commonly used in metalworking and fabrication shops.

4 Air Sanders: Perfect for smoothing surfaces, air sanders are used in woodworking, automotive bodywork, and furniture making.

5 Air Drills: These are used for drilling holes in various materials, including wood, metal, and plastic. They are preferred for their lightweight and high-speed operation.

6 Air Blow Guns: These tools are used for cleaning and drying surfaces by blowing away dust and debris.

Applications of Air Tools

Air tools are indispensable in many fields due to their reliability and performance. In the automotive industry, they are used for tasks such as tire changing, engine repair, and bodywork. In construction, air tools are used for framing, roofing, and finishing work. Manufacturing industries use air tools for assembly lines, metal fabrication, and maintenance tasks.

Benefits of Air Tools

1 Power and Efficiency: Air tools provide more power compared to their electric counterparts. They can handle heavy-duty tasks with ease, making them ideal for industrial applications.

2 Durability: Air tools are built to withstand harsh working conditions. They have fewer moving parts, which reduces the risk of wear and tear, leading to a longer lifespan.

3 Safety: Air tools are generally safer to use in hazardous environments. They do not produce sparks, making them suitable for use in flammable or explosive atmospheres.

4 Cost-Effective: Although the initial investment in an air compressor and air tools can be high, the long-term benefits and reduced maintenance costs make them a cost-effective choice.

5 Versatility: With a wide range of tools available, air tools can be used for various applications, from simple household tasks to complex industrial operations.

Conclusion

Air tools and equipment have revolutionized the way we approach various tasks in different industries. Their power, efficiency, and versatility make them an invaluable asset in any workshop or job site. As technology advances, we can expect even more innovative and efficient air tools to emerge, further enhancing productivity and safety in the workplace.

Data sheet

- Warranty

- Unavailable

- Quality rating by Rastegar Sanat from 0 to 100

- 70

- Made in

- china

- استاندارد

- available

You can also share your opinion about this product

To submit a review, please sign in to your account first.

No reviews yet.

You can also ask your own question about this product To submit a question, please sign in to your account first.

Sign in to submit a questionNo questions yet.