RSCO water leak detector WLD4

Informtion:

RSCo professional manual leakage finder:

- Able to find digitally any leakage under pressure .

- Including Digital LCD 7 inches HD Touch screen .

- Includes voice amplifier with modulation voice controller for filtering up 10 levels

- Ability to work on depth : 50 cm

- Deletes different voice frequencies.

- Able to find leakages even pointwise and limited in surroundings.

- Includes sensitive and qualified headphones.

- Working time : 15 H .

- Multi-language menu

- Operation system : rechargeable

- Aluminum box for easy portation

- Frequency range of this leak detector : 100000HZ-1.

- Charging time : 7-8 h .

- Equipped with Triangle sensor .

- Weight : 8Kg .

- Includes ISO9001 and CE from Eueope unioun.

- For more info contact us via webpage.

Introducing the water leak detection device:

The water leak detector includes the following:

- Volume, volume, LED, indicator light, battery level, sensitivity, power switch, filter, color display, intermittent mute switch, charger connector, headphone, loop, loop cable.

Water leak detector features Water pipe:

- Leak Detector has full digital design.

- Water leak detection device equipped with rechargeable battery system with automatic charger.

- SENSOR DETECTION SENSOR DIRECTOR for low or high sensitivity of the device.

- Filter leakage leakage tube to get better sound for metal and non-metallic pipes.

- Sewer pipe leakage lever equipped with Digital Signal indicator.

- Water leakage leakage device with loop or highly sensitive receiver with IC amplification.

- Plumbing leak detector A powerful sound playback of up to 1000MW through the headphones supplied with the device.

- Professional leak detector with professional frequency headband 20HZ-20KKZ.

- MUTE leak detection device for use in loop movement to prevent ear infections.

- The water leak detection device is very low-power and has a battery life of up to 40 hours.

- Two year warranty and ten years after sales service leak detector.

- Manual leak detection device Voltage 12 volt leak detector with internal and rechargeable battery.

- Battery life 40 hours continuous leak detection device if fully charged.

- Charging the 220V battery to 12V full-automatic.

- 1000 MW audio output power on headphones.

- The weight of the water pipe leakage is less than 500 grams.

The structure and operation of the sewage pipe leakage detector system:

- In designing and manufacturing this water leak detector, we have been working hard to make use of the latest and most sophisticated parts in the world.

- Therefore, the use of the latest integrated circuits has led to a high quality and sensitivity of the devic

- Which has a 10-megapixel impedance so that the signals can be amplified too weakly.

- The looping design of the leak detector, which is responsible for receiving signals from the ground or any other surface, is no exception.

- And with the use of highly sensitive ICs, we tried to increase the loop sensitivity and potency as much as possible.

- In addition, using this special design, transmission of received loop signals to the device through the corresponding cable does not involve any voltage drop.

- This precise, sensitive design, and the structure and sustainability of this system, which provides a 20Hz-20KHZ frequency band.

- Enables the user to use this device for leakage of water in low pressure and high pressure systems.

- In designing this device to avoid battery replacement as one of the users' concerns, rechargeable batteries with a fully charged charger have been used to avoid over-the-air power supply.

- The user will only use the device after hours of use to connect the charger to the city and the device for recharging.

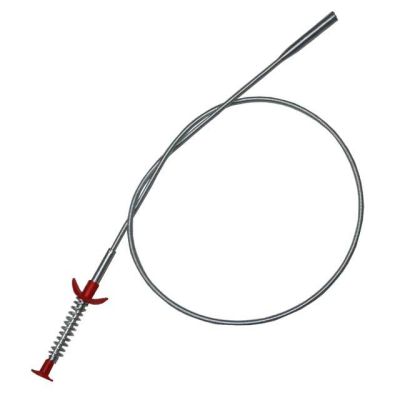

Alloys loop:

- In the design of this loop, an aluminum plate with 3 bases is used to receive signals from leakage of water pipes.

- Also, within the loop, there is no Integrated Circuit (IC) to amplify the highest received signal level to noise (S / N).

- This has caused a very high sensitivity and a very low noise level.

- Due to the acoustic nature of the loop environment, the conversion of very poor motor-to-noise signals into looped aluminum surfaces is possible.

How water leak detection devices work:

- When it flows through a metal pipe or non-metallic pipe. And the tubing will be leaked due to decay or for any other reason. The water inside the pipe is removed by pressure from the leakage site.

- Due to the outflow of water, a sound is generated that changes the sound to the ground.

- The above sound is made by the loop of the leak detector, which is responsible for receiving very poorly-designed products.

- After boosting and filtering, the leak detector itself is transmitted and after several rebuilding steps on the device itself, the output of the leak detector is amplified.

- This way, you can find the exact location by receiving and hearing the tallest audio signal that corresponds to the sound of the pressure drop from the leakage point.

- Water pressure inside the pipe is very important

- Generally, the pressure inside the pipe should not be less than 2 times 30PSi.

- Leakage noise will be noticeably reduced when water pressure is less than this value.

- In this case, it is recommended to use telescopic rods to get closer to the leak and get better sound.

To improve leakage performance, the following is recommended:

- Observe silence at the place of leakage

- Turn off electrical appliances that produce noise and noise.

- Ensure water coolers are closed

- Use a telescopic rod to leak out the main tube after the meter

Automatic Charger:

- Connect the device to the city's power to charge the battery of the charger.

- Connect the charger plug to the charger on the device.

- The device should be in silent mode when charging the power key.

- When recharged, the LED on the charger is in red. After charging the batteries, lED will change green.

Read more about other products of the industry:

- PPR pipe is a specially designed plumbing fixtures for ppr pipe,PPR and steel pipe, ppr heating whitewashing heating plumbing, plastic welds, and ppr pipe

- For more information and prices, please contact the sales office.

- PPR pipe cutters such as pipe cutter, pipe cutters, ppr pipe cutting ppr white tube shears, electric pipe cutter, pe pipe cutter, plumbing cutter, for cuttingppr and pe pipes.

- A PPR pipe welding machine consists of several mouths (green tube caliber) that is performed by bringing the boiling temperature to the boiling point.

- A welding machine with a name of plastic welding machine, a second-line polyethylene welding machine, a fully-welded polyethylene welding machine, a plastic welding machine, a pipe-welded pipe and polyethylene fittings of 63 to 160 mm in size.

- Polyethylene welding iron is also capable of welding all polyethylene pipes.

- PE Polypropylene pipes are used to cut pe and propylene pipes from 50 to 127 mm in size.

- The Polypropylene Tube Wrench is an industry capable of opening and closing all kinds of polyethylene fittings and PVC fittings.

- PEX pipe presses include five-layer, five-layer,pex ,pex pipe presses, pex pipe hydraulic presses.

- All PEX, five-piston pipe presses have pex connectors (SuperPyp, UnixPipe, NewPipe).

- The outer layer of the five-layer pipe can be penetrated by apex pipe.

- The five-layer pipes can be bent with a five-layer pipe, and they are riveted to penetrate the five-layer tubes by a five-layer pipe riveting.

- To bend these types of pipes, thepex industrial pipe bender is used.

- To keep the pipe in the shape of a deformation, you can use the roller of the five-layer industrial pipe.

- The Industrial Pump Test Machine has been designed with a unique design, light weight to test and test the piping of pipelines and reservoirs.

- rastegar Industrial Company is able to repair the water piping test machine. So you can refer to the office of Rastgar Industry for the repair of the water pipe testing machine

- To leak the pressure pipes, we introduce the industry-leading mini-leak detector. The industry has gas leak detectors.

- For repairs of polyethylene welding machines, polyethylene boiling heater , ppr pipe iron, pump testing machine, pex pipe presses, welding inverters and leak detectors, please refer to the sales office of the industry.

- Stainless steel extruder is also used to repair pipe and fittings of polyethylene.

- The high-pressure welding extruder of the industry is used as a welding pipe and polyethylene fittings.

- Due to the fact that steel and galvanized pipes are used today, electric devices are used to carry out these types of pipes.

- The industrial scrapper is used to peel pe pipes.

- The squzeer is used to block the transmission of polyethylene pipes

- Cutting of polyethylene pipes from a size of 25-160 mm is done by pipe on guillotine.

- Multi-clamp is also used to hold polyethylene pipes during welding.

- The clamping of polyethylene pipes is used to hold the polyethylene pipes at the welding time.

- Welding Industry has the ability to weld various types of plastic surfaces in PVC, PP, polyethylene.

- The Rossabor copper tube has the ability to cut all kinds of copper and aluminum pipes. And Ripper is a steel wire mesh made of high alloy steel

- Hydraulic bender The five-layer industrial pipe is used to bend all kinds of steel, steel, copper and aluminum pipes.

- Hydraulic polisher is used to get all kinds of industrial money.

- The hand pump is used for winding up to a maximum of 1.9 times.

Data sheet

- Name

- RSCO water leak detector

- Device Model

- WLD4

- Power

- 2 watt

- Input voltage

- 220-230 V

- After-sale services

- 1year

- Function system

- rechargeable

- Operating temperature

- ( -20 ℃~ +50 ℃ )

- Frequency

- 100000HZ-1

- Warranty

- 1year

- Accessories

- available

- Quality rating by Rastegar Sanat from 0 to 100

- 80

- Shipping Box

- Available

- Weight

- 8kg

- Charging time

- 8-7 hours

- نوع دستگاه

- water leak detector

You can also share your opinion about this product

To submit a review, please sign in to your account first.

نشت یاب آب دیجیتال رستگار صنعت مدل WLD4

دستگاه موجوده؟

نشت یاب آب دیجیتال رستگار صنعت مدل WLD4

واقعا عالی دست مریزاد حرف نداره

You can also ask your own question about this product To submit a question, please sign in to your account first.

Sign in to submit a questionNo questions yet.