RSCO Mini Bench Lathe model BLWM210V

Turning Machine

Specifications:

- A bench lathe machine is a versatile and essential tool in the field of precision machining

- Suitable for turning all kinds of metal and plastic surfaces and...

- The largest working diameter for turning the machine head : 210 mm

- Maximum workable diameter to the surface of the machine : 140 mm

- Workable length : 300 mm (Also with the ability to choose between 600 and 800 mm)

- Screw size in mm : 0.089.0/0.198

- Screw size in inches : 14/0.3-3 TPI

- power : 750 w

- voltage : 220 V and 50 Hz / 110 V and 60 Hz

- Headstock Spindle Taper : MT2

- spindle size : 38 mm

- Equipped with LCD to display the engine speed

- Has a screw cutting system

- Equipped with all steel gearbox

- Speed : 50 to 2500

- weight : 70 kg

- Made in China

- If repairing of the bench lathe machine is needed call repairing department of Rastegar Sanat

- For more information about the price of the bench lathe call selling department of Rastegar Sanat

Bench Lathe Machine: An Essential Tool in Precision Machining

A bench lathe machine is a versatile and essential tool in the field of precision machining. It is designed to perform various operations such as cutting, sanding, knurling, drilling, and turning, which are crucial in shaping metal or wood workpieces. This essay explores the components, functions, and applications of bench lathes, highlighting their significance in both industrial and hobbyist settings.

Components of a Bench Lathe

A bench lathe consists of several key components that work together to achieve precise machining:

1 Lathe Bed: The foundation of the lathe, providing stability and support for all other components.

2 Headstock: Houses the spindle and motor, responsible for rotating the workpiece.

3 Tailstock: Positioned opposite the headstock, it supports the workpiece and can hold tools for drilling or reaming.

4 Carriage: Moves along the bed and holds the cutting tool, allowing for precise control over the machining process.

5 Tool Post: Mounted on the carriage, it secures the cutting tool in place.

6 Chuck: Attached to the spindle, it grips the workpiece firmly.

7 Cross Slide and Compound Rest: Allow for lateral and angular movement of the cutting tool, enabling intricate cuts and shapes.

Functions and Operations of Bench Lathe

Bench lathes are capable of performing a wide range of operations, making them indispensable in various machining tasks:

• Turning: The primary function, where the workpiece is rotated while a cutting tool shapes its exterior.

• Facing: Creating a flat surface at the end of the workpiece.

• Drilling: Using the tailstock to hold a drill bit, holes can be precisely drilled into the workpiece.

• Knurling: Producing a textured pattern on the surface for better grip.

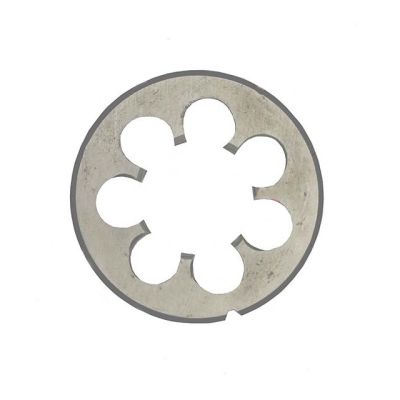

• Threading: Cutting threads on the exterior or interior of the workpiece for screws and bolts.

Applications of Bench Lathes

Bench lathes are used in numerous industries and by hobbyists for various applications:

• Manufacturing: Essential in producing parts for machinery, automotive components, and aerospace parts.

• Prototyping: Ideal for creating prototypes and custom parts with high precision.

• Jewelry Making: Used by jewelers to shape and polish metal pieces.

• Woodworking: Employed by woodworkers to create detailed and intricate designs.

Advantages of Bench Lathes

The bench lathe offers several advantages that make it a preferred choice for precision machining:

• Versatility: Capable of performing multiple operations on a single machine.

• Precision: Allows for high accuracy in shaping and cutting materials.

• Compact Size: Fits on a workbench, making it suitable for small workshops and hobbyists.

• Cost-Effective: Provides a cost-efficient solution for various machining tasks.

Conclusion

In conclusion, the bench lathe machine is a fundamental tool in the realm of precision machining. Its versatility, precision, and compact size make it an invaluable asset in both industrial and hobbyist settings. Whether used for manufacturing, prototyping, or crafting intricate designs, the bench lathe continues to play a crucial role in shaping the world of machining.

Data sheet

- Name

- Turning Machine

- Size

- 210 mm

- Input voltage

- 220 V and 50 Hz / 110 V and 60 Hz

- Function system

- electric

- Production material

- steel

- Speed

- 50-2500 rpm

- Made in

- china

- Weight

- 70 kg

- قدرت دستگاه تراش

You can also share your opinion about this product

To submit a review, please sign in to your account first.

No reviews yet.

You can also ask your own question about this product To submit a question, please sign in to your account first.

Sign in to submit a questionNo questions yet.